Zero Impact Factory

Vision of the “Zero Impact Factory”

The vision of the “Zero Impact Factory” describes a factory that produces in a climate-, resource- and environmentally friendly manner and thus avoids environmental impacts in vehicle and component production. The “Zero Impact Factory” envisions an idealized ecological factory implemented through our strategic processes across brands and sites. A systematic and method-based approach is used in order to measure and control the ecological transformation.

From vision to implementation: the “Zero Impact Factory”

Environmental protection is more than just climate protection. Together with many colleagues around the world, an ecological factory concept for the vision of the “Zero Impact Factory” was developed that is intended to enable production without any negative impact on the environment.

To measure and control the progress toward the “Zero Impact Factory,” there are evaluation methods that have been developed together with external experts. These are used to measure, evaluate and control the ecological quality of a production site both qualitatively and quantitatively.

All sites for the production of passenger cars and light commercial vehicles collect the following data and information:

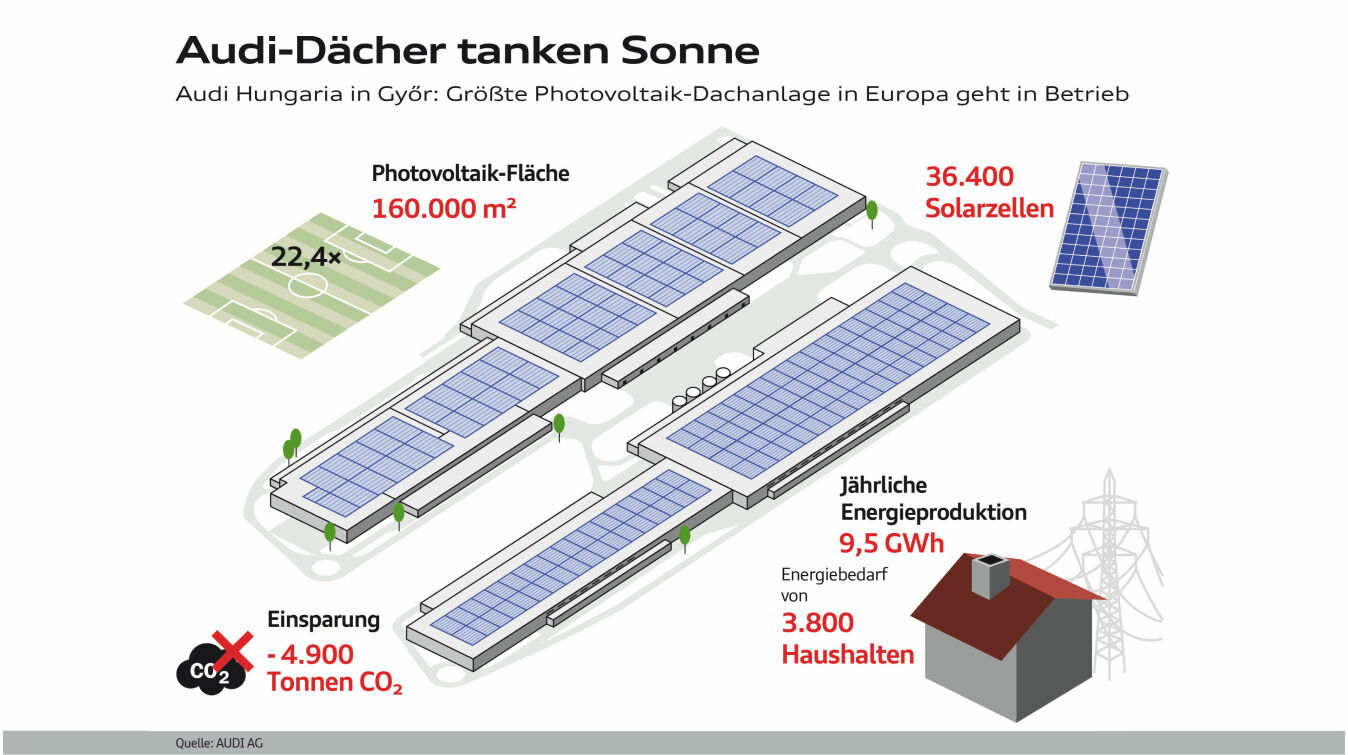

22 quantitative environmental indicators such as CO2 emissions, solvent emissions, fresh water consumption, wastewater loads or various types of waste are measured on site and converted into impact points. This means that the absolute environmental impacts can be compared with each other and targeted reduction measures can be applied where they have the greatest impact.

143 predefined qualitative environmental criteria that cannot be easily quantified are continously reviewed with regard to their implementation status using the Site Checklist. Examples include specific projects to preserve biodiversity at the site, the creation of framework conditions for environmentally friendly employee mobility, and measures to promote the circular economy.

Starting in 2025, this “Zero Impact Factory” methodology is intended to shift from purely performance-based indicators to a reduction in the absolute environmental impact of our production processes. The goal is to achieve zero-impact status for all sites producing passenger cars and light commercial vehicles by 2050. (Source: Volkswagen Group Sustainability Report 2022)

Impact Points Ticker

A preliminary analysis during the test phase shows that since 2018, environmental impact (measured in impact points) has already been reduced by

More in-depth information

“Environmental protection must be a natural part of our daily activities.”